Exploring the Top Features of the Best Large Drain Pan for Global Buyers

As we delve into the evolving landscape of automotive maintenance and fluid management in 2025, the significance of a reliable large drain pan cannot be overstated. According to a recent report by Market Research Future, the automotive maintenance market is projected to grow at a CAGR of 6.2%, driven by advancements in technology and increasing vehicle ownership worldwide. Among the essential tools in this realm, the large drain pan stands out for its versatility and efficiency in capturing waste fluids, ensuring not only a cleaner working environment but also compliance with environmental regulations. With the growing emphasis on sustainability, global buyers are increasingly seeking drain pans that offer innovative features, such as enhanced durability, leak-proof designs, and easy portability, making the exploration of the top features of the best large drain pan a timely and relevant topic.

Top Features to Look for in Large Drain Pans for 2025 Industry Trends

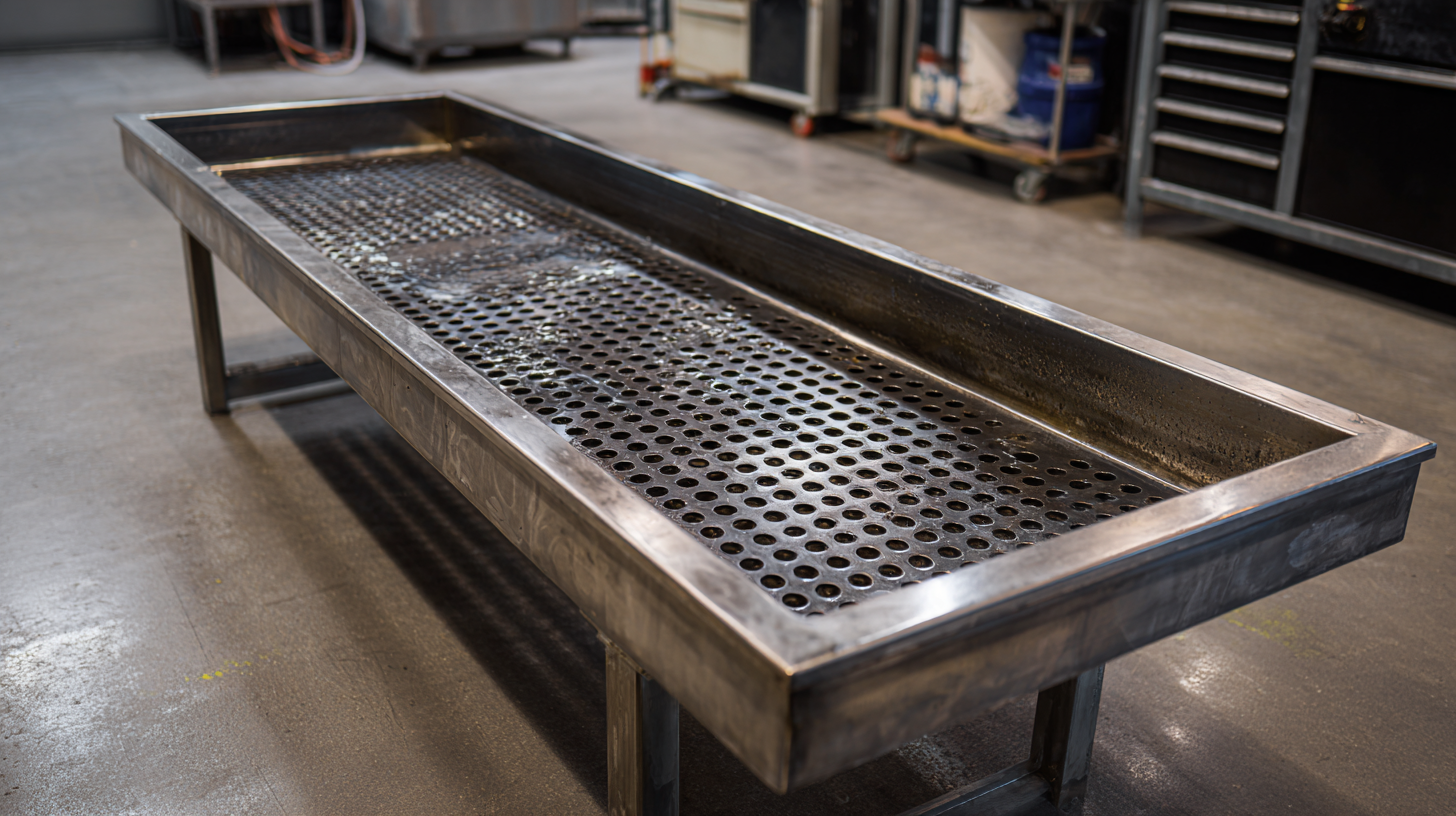

When selecting a large drain pan in 2025, industry trends highlight several crucial features that buyers must consider. First and foremost, material durability is paramount. High-quality materials like heavy-duty polyethylene or galvanized steel not only enhance the longevity of the pan but also improve resistance to rust, corrosion, and chemical damage. This is especially important for industrial environments where spills can occur frequently. A well-constructed pan will withstand the rigors of regular use while maintaining its efficiency.

Another key feature to look for is size versatility. As industries evolve, so do their needs; therefore, a pan that can accommodate various sizes of equipment is essential. Multi-purpose drain pans with a capacity to handle larger spills or multiple sources of liquid are increasingly popular. Additionally, consider designs with integrated drainage systems or spouts that facilitate easy emptying and transportation, reducing the risk of spills and promoting safety in the workplace. By focusing on these emerging features, global buyers can make informed decisions that enhance both operational efficiency and safety standards in 2025.

The Impact of Material Quality on the Durability of Drain Pans in 2025

As the demand for high-quality drain pans continues to rise, the material quality has emerged as a significant factor influencing durability. According to a report by Industry Research Insights, the global drain pan market is projected to reach $1.8 billion by 2025, with a notable emphasis on materials like polyethylene, steel, and aluminum due to their capacity to withstand various environmental challenges. For instance, polyethylene drain pans provide excellent resistance to corrosion, making them ideal for use in chemical or oil environments, while aluminum versions offer a lightweight solution without sacrificing strength.

In 2025, consumers are increasingly prioritizing durability over cost, with 67% of buyers willing to invest in higher-quality materials that promise longevity (Market Trends Analysis, 2023). This shift reflects a growing awareness of the long-term savings associated with more durable options. Furthermore, companies are innovating by incorporating advanced manufacturing techniques to improve the structural integrity of these products, ensuring they meet the rigorous demands of both commercial and residential applications. As we move forward, the interplay between material quality and product performance will undoubtedly shape the landscape of the drain pan market.

Exploring the Top Features of the Best Large Drain Pan for Global Buyers - The Impact of Material Quality on the Durability of Drain Pans in 2025

| Feature | Material Type | Durability Rating (out of 5) | Corrosion Resistance (Yes/No) | Weight Capacity (lbs) |

|---|---|---|---|---|

| Leak Prevention | Stainless Steel | 5 | Yes | 300 |

| Heat Resistance | Aluminum | 4 | No | 250 |

| Anti-Slip Surface | PVC | 3 | No | 200 |

| Easy Cleaning | Polyethylene | 4 | Yes | 150 |

Understanding Size and Capacity: Choosing the Right Large Drain Pan

When selecting the right large drain pan, understanding size and capacity is crucial for both efficiency and effectiveness. According to a recent industry report by *Market Insights*, the demand for drain pans with a capacity exceeding 20 quarts has surged by 30% over the past two years, highlighting the trend towards larger capacity models that accommodate various automotive and industrial applications. Buyers should consider not only the dimensions but also the volume needed for their specific tasks, as an appropriate capacity can prevent spillovers and enhance workflow.

Tip: Always measure the space where the pan will be used, and check the specifications of the equipment involved to ensure compatibility. A large pan with a capacity that is too small will lead to frequent emptying and can cause unnecessary downtime.

Furthermore, material selection plays a significant role in the pan's performance. High-density polyethylene (HDPE) and galvanized steel are among the most recommended materials, providing durability and resistance to chemicals and heat. A study conducted by the *National Institute for Standards* indicated that drain pans made from HDPE can withstand temperatures up to 120°F without deformation, making them a reliable choice for various settings.

Tip: Look for pans with reinforced edges and anti-spill designs to maximize efficiency and safety. When choosing a drain pan, focus on features that suit your specific needs, ensuring the best fit for your operations.

Cost-Effectiveness Analysis: Best Value Large Drain Pans for Global Buyers

When it comes to purchasing a large drain pan, cost-effectiveness is a crucial factor for global buyers seeking the best value for their money. The ideal large drain pan should combine high-quality materials and practical design without breaking the bank. Options made from durable plastic or heavy-duty metal often offer long-lasting performance while providing the necessary capacity to handle spills from various vehicles and equipment.

Examining the price-to-quality ratio can help buyers identify products that deliver both reliability and affordability.

Additionally, buyers should consider features such as compatibility with different applications and the ease of cleaning. Innovative designs that allow for better drainage and sturdy construction can enhance the overall value proposition of a drain pan. For global customers, purchasing in bulk or taking advantage of seasonal promotions can also lead to significant savings. Evaluating these factors will ensure that buyers make informed decisions, ultimately securing the best deals available in the market.

Innovative Designs in Drain Pans: Sustainability and Efficiency in 2025

As we move towards a more sustainable future, the design of large drain pans has evolved significantly to address the growing demands of efficiency and environmental responsibility. Innovative materials, such as recycled plastics and bioplastics, are making their way into the production of these essential tools. In 2025, manufacturers will prioritize not only durability but also the ability to minimize waste and energy consumption during the manufacturing process. This shift in focus reflects a broader trend towards sustainable manufacturing practices across various industries.

In addition to sustainable materials, the functionality of drain pans has also seen a transformation. Enhanced designs with improved drainage capabilities and ease of cleaning are essential features that appeal to global buyers. The integration of ergonomic designs allows for better handling and transportation, making these drain pans more user-friendly. As the market evolves, features such as modular designs and customizable options are likely to gain popularity, catering to diverse consumer needs while maintaining a commitment to sustainability. This convergence of innovation and environmental consciousness is set to redefine the landscape of drain pan manufacturing, ensuring that these tools meet modern challenges head-on.

Exploring the Top Features of the Best Large Drain Pan for Global Buyers

This chart illustrates the top features of large drain pans as preferred by global buyers in 2025, highlighting the focus on sustainability, design innovation, and efficiency. The features measured include Material Durability, Eco-friendliness, Design Efficiency, Cost-effectiveness, and User Reviews.