How to Choose the Best Vacuum Forming Machine for Your Business Needs

In today's fast-paced manufacturing landscape, selecting the right vacuum forming machine is essential for businesses aiming to enhance their production efficiency and product quality. According to a recent report by IBISWorld, the global market for vacuum forming machinery is projected to grow steadily at a CAGR of 5.2% over the next five years, driven by increasing demand in sectors such as packaging, automotive, and consumer goods. As companies seek to optimize their operations and reduce costs, understanding the benefits of different types of vacuum forming machines becomes imperative. This guide will provide insights into key factors to consider when choosing a vacuum forming machine that aligns with your specific business needs, ensuring you stay competitive and meet evolving market demands.

Key Market Trends in the Vacuum Forming Industry by 2025

The vacuum forming industry is anticipated to experience significant growth, with a projected market value reaching approximately $3.6 billion by 2025, according to a report by Mordor Intelligence. This trend is driven by an increasing demand for lightweight, versatile packaging solutions across various sectors, including food, automotive, and electronics. As businesses strive for sustainable practices, the shift towards eco-friendly materials in vacuum forming is becoming a priority, reflecting a global emphasis on reducing environmental impact.

In addition to sustainability, technological advancements are shaping the industry landscape. The integration of automation and smart technology into vacuum forming machines is expected to enhance production efficiency and precision. A report from MarketsandMarkets highlights that the adoption of automated solutions could reduce manufacturing costs by up to 20%, making it an attractive option for businesses looking to scale their operations. As these key trends unfold, companies will need to carefully evaluate their machinery options to align with their operational goals while staying competitive in an evolving market.

Understanding Different Types of Vacuum Forming Machines for Various Applications

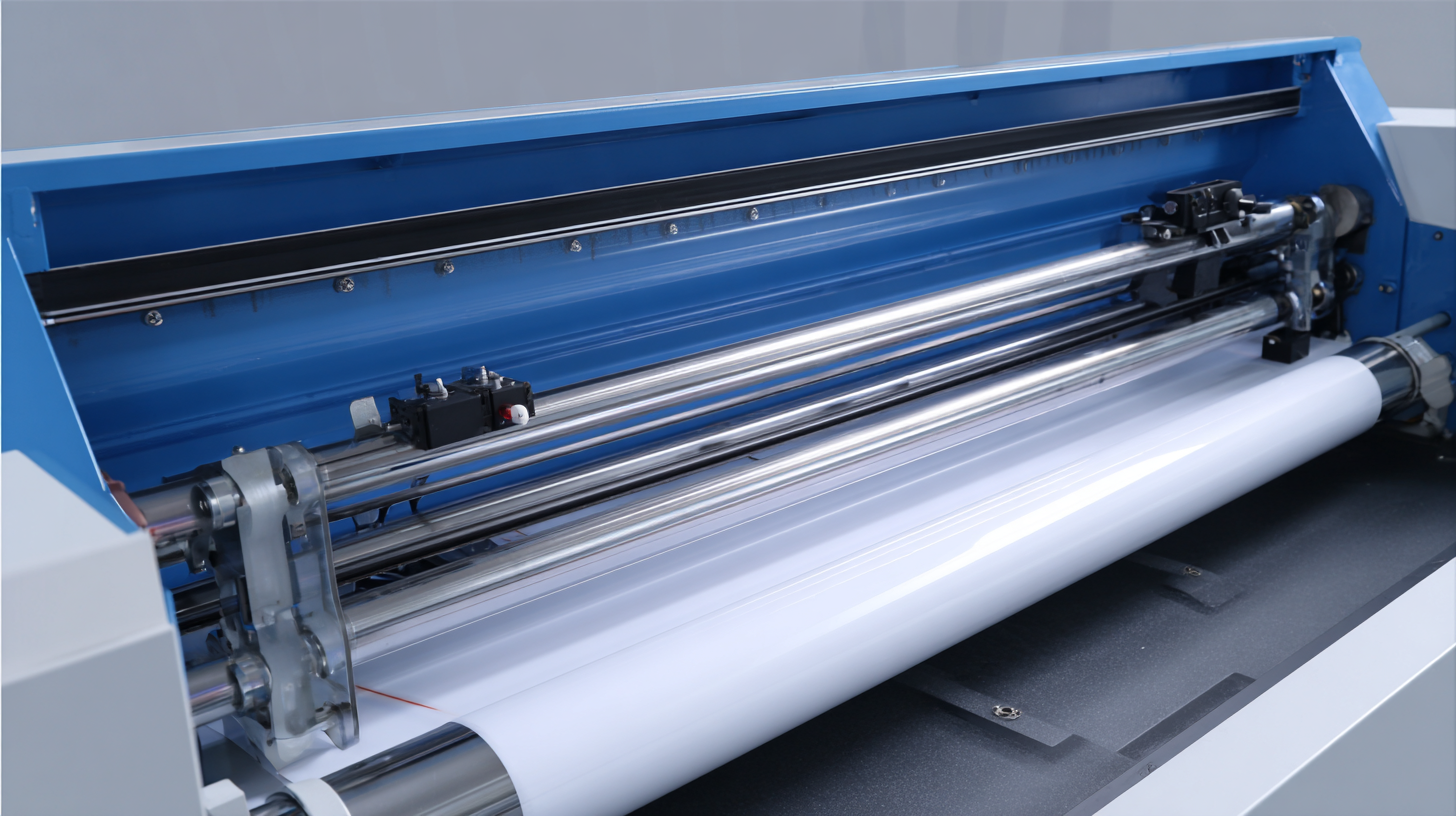

When selecting a vacuum forming machine for your business, it's essential to understand the various types available and their specific applications. Vacuum forming machines can be broadly categorized into two main types: sheet-fed and roll-fed machines. Sheet-fed machines are ideal for small to medium production runs, as they allow for quick changeovers and flexibility in design. They are particularly suited for applications like packaging, signage, and custom prototypes, where versatility and precision are paramount.

On the other hand, roll-fed machines are designed for high-volume production, making them perfect for industries that require consistent output, such as automotive parts or large-scale packaging materials. These machines utilize rolls of thermoplastic, which can be fed continuously into the forming process, significantly increasing efficiency and lowering material waste. Understanding the differences between these types of machines will help businesses make informed decisions that align with their production needs and overall operational goals.

Evaluating Specifications: What to Look for in a High-Quality Vacuum Forming Machine

When evaluating specifications for a high-quality vacuum forming machine, several key factors must be considered to ensure that the equipment meets your business needs. One of the primary specifications is the machine's sheet size capability. According to a report by Research and Markets, the demand for larger sheet forming machines has increased by over 25% in the last five years, driven by industries such as automotive and packaging. A machine that can accommodate larger sheets will enhance production efficiency and open opportunities for more complex designs.

Another critical aspect to consider is the heating efficiency and temperature control features of the vacuum forming machine. Industry studies indicate that machines with advanced heating systems can reduce cycle times by as much as 30%, leading to increased productivity and cost savings. Additionally, precise temperature control not only helps in achieving consistent forming results but also extends the lifespan of the heating elements, lowering maintenance costs over time. Therefore, understanding these specifications is essential for making an informed investment in a vacuum forming machine that aligns with your strategic operational goals.

Cost-Benefit Analysis: Investing in Vacuum Forming Machines for Your Business

Investing in a vacuum forming machine can yield significant benefits for your business, but it is essential to conduct a thorough cost-benefit analysis to ensure that you make the right decision. One of the primary benefits of vacuum forming is its efficiency in producing high-quality plastic parts at a relatively low cost. This process reduces material waste and allows for rapid prototyping, which can accelerate your product development cycle. By understanding the long-term savings on materials and labor, businesses can gauge the potential return on investment and justify the initial expense.

Moreover, the versatility of vacuum forming machines plays a crucial role in their value proposition. These machines can be utilized across various industries, including packaging, automotive, and consumer goods. By analyzing the specific needs of your operations, you can determine how a vacuum forming machine can enhance production capabilities and meet market demands. The ability to quickly create custom molds means that businesses can remain agile and competitive, adapting products to consumer preferences without incurring overwhelming costs. Thus, a well-considered investment in vacuum forming technology can be a game-changer, providing both immediate and long-term financial advantages.

How to Choose the Best Vacuum Forming Machine for Your Business Needs - Cost-Benefit Analysis

| Machine Model | Initial Cost ($) | Operating Cost (Annual) ($) | Production Rate (Units/Hour) | Material Compatibility | Average Lifespan (Years) | Customer Satisfaction Rating (Out of 5) |

|---|---|---|---|---|---|---|

| Model A | 10,000 | 2,000 | 50 | ABS, PVC | 5 | 4.5 |

| Model B | 15,000 | 3,500 | 60 | PETG, PS | 6 | 4.7 |

| Model C | 12,000 | 2,500 | 55 | PP, PE | 5 | 4.3 |

| Model D | 20,000 | 4,000 | 70 | PVC, HIPS | 7 | 4.8 |

Case Studies: Successful Implementations of Vacuum Forming Solutions in Various Sectors

Vacuum forming has emerged as a pivotal technology across various industries, demonstrating its capacity to enhance production efficiency and product quality. A report from Smithers Pira notes that the global vacuum forming market is projected to reach $3.9 billion by 2025, driven by the growing demand for customized packaging solutions. The case of a leading automotive manufacturer exemplifies this trend, where the integration of vacuum forming techniques allowed for the rapid prototyping of parts, significantly reducing lead times by 40%. This adaptability not only streamlined their production process but also improved their ability to meet changing consumer demands.

In the packaging sector, a notable example is a food packaging company that adopted vacuum forming for creating packaging trays. By leveraging this technology, they reduced material waste by 30%, as reported by a study from Mordor Intelligence. This innovative approach not only enhanced their sustainability efforts but also translated into cost savings that bolstered their competitive edge in the market. Such implementations across diverse sectors illustrate how selecting the right vacuum forming machine can lead to transformative impacts on operational efficiency and business growth.