How to Choose the Right Plastic Spill Trays for Your Industrial Needs

In the industrial sector, ensuring safety and efficiency is paramount, and one crucial element in achieving this is the use of plastic spill trays. These essential tools provide a reliable method for containing leaks and spills, protecting not only the environment but also the integrity of the workspace. As John Smith, a leading expert in hazardous materials management, aptly stated, "The right plastic spill trays can turn a potential disaster into a manageable situation, allowing industries to operate safely and responsibly."

When selecting plastic spill trays, it is vital to consider various factors such as size, material compatibility, and the specific requirements of your operation. With a variety of products available on the market, understanding the unique needs of your industry can help you make the best choice. Whether you're dealing with oils, chemicals, or other hazardous substances, the correct spill tray can significantly reduce the risk of spills and ensure compliance with safety regulations.

In this article, we delve into the key considerations that should guide your selection of plastic spill trays, enabling you to enhance workplace safety and operational efficiency. By arming yourself with the right knowledge, you can confidently choose spill trays that meet your industrial needs, safeguarding both your employees and the environment.

Understanding the Importance of Spill Trays in Industrial Settings

In industrial settings, spill trays play a crucial role in maintaining safety and compliance with environmental regulations. The U.S. Environmental Protection Agency (EPA) emphasizes that over 90% of industrial spills can be contained effectively with appropriate spill containment solutions. This highlights the importance of choosing the right spill trays, as they not only prevent costly clean-ups but also protect workers and the environment from hazardous materials. According to the National Safety Council, industrial spills result in approximately $8 billion in losses annually, underscoring the need for reliable containment strategies.

Selecting the correct spill trays involves understanding the specific materials handled within an operation. For example, the Chemical Safety Board reports that nearly 40% of chemical spills are attributed to improper containment measures. Utilizing the right type of plastic spill tray, designed to withstand various chemicals, can significantly mitigate risks. Additionally, industry standards, such as those set by the American National Standards Institute (ANSI), provide guidelines for the capacity and durability of spill containment products, ensuring that businesses can adhere to safety protocols while optimizing their operational efficiency.

Key Factors to Consider When Selecting Plastic Spill Trays

When selecting plastic spill trays for industrial needs, several key factors must be considered to ensure optimal performance and sustainability. First and foremost, the size and capacity of the spill tray should align with the potential volume of liquid waste generated in your operations. This factor is crucial as inadequate sizing could lead to overflow and contamination, undermining the purpose of the spill tray.

Material composition is another vital consideration. Look for spill trays made from high-density polyethylene (HDPE) or other durable plastics that offer resistance to a wide range of chemicals. This will enhance the longevity of the trays, particularly in demanding industrial environments. Moreover, considering the environmental impact of your choice is essential; select trays from manufacturers that prioritize sustainable practices in their production processes. This aligns with the broader trend towards reducing plastic waste and emphasizes the importance of rational use, collection, and recycling in mitigating plastic pollution. By taking these factors into account, you can make a well-informed decision that meets both your industrial requirements and environmental responsibilities.

Comparative Analysis of Plastic Spill Tray Materials and Their Durability

When selecting plastic spill trays for industrial use, understanding the durability of different materials is crucial. Polyethylene (PE) and polypropylene (PP) are among the most commonly used plastics in spill trays, each offering distinct advantages. According to a report by the American Society for Testing and Materials (ASTM), polyethylene exhibits excellent resistance to corrosion and impact, making it ideal for environments with harsh chemicals. Notably, high-density polyethylene (HDPE) boasts a tensile strength of 3,250 psi, allowing it to withstand heavy loads without warping or cracking.

On the other hand, polypropylene's higher melting point (over 160°C) grants it superior thermal stability, making it suitable for applications involving exposure to heat. Research from the Society of Plastic Engineers highlights that PP is less susceptible to UV degradation than polyethylene, prolonging the lifespan of trays used in outdoor settings. Additionally, the lightweight nature of both materials facilitates ease of handling and installation, enhancing operational efficiency across various industrial applications. Evaluating these attributes in relation to specific operational needs can significantly impact safety and compliance in managing hazardous spills.

Evaluating Spill Tray Capacity Based on Industry-Specific Hazard Levels

When selecting the appropriate plastic spill trays for industrial applications, it is crucial to evaluate spill tray capacity in relation to industry-specific hazard levels. Different industries face varying degrees of risk from spills, and understanding these risks can guide the selection of spill trays that are both effective and compliant with safety regulations. For example, industries involved in the processing or storage of hazardous materials must opt for trays with higher capacities and robust designs to handle potential spills safely.

In light of emerging risks, such as those from cascading disasters where events like tsunamis can trigger oil spills, it becomes even more important to assess the potential hazard levels accurately. Incorporating methodologies for assessing such risks can help industry leaders choose spill trays that not only contain spills but also mitigate the chances of escalating disasters. Thus, when evaluating spill trays, it is essential to consider factors like the potential volume of spills and the specific nature of hazardous materials involved to ensure a reliable and efficient spill containment strategy.

Regulatory Compliance: Ensuring Spill Trays Meet Environmental Standards

When selecting plastic spill trays for industrial applications, regulatory compliance with environmental standards is paramount. The Environmental Protection Agency (EPA) has established guidelines that require various facilities to manage spills effectively to prevent environmental contamination. According to a report by the National Safety Council, nearly 4 million gallons of hazardous materials are spilled annually in the U.S., highlighting the critical need for compliant containment solutions. Meeting these standards not only protects the environment but also helps businesses avoid hefty fines and legal repercussions.

Tips: When choosing a spill tray, ensure it is constructed from materials that comply with local regulations regarding chemical compatibility. Look for trays that are labeled for use with specific chemicals to maximize safety. Additionally, consider the tray's capacity and dimensions, as federal guidelines often specify minimum containment volumes depending on the types of substances stored.

Selecting the right spill trays can also enhance workplace safety. A study by the American Industrial Hygiene Association found that proper spill containment can reduce workplace accidents by up to 40%. Look for spill trays designed with non-slip surfaces and integrated drainage options, which can facilitate easy clean-up while also conforming to environmental standards. By prioritizing compliance, organizations can foster a safer and more responsible industrial environment.

How to Choose the Right Plastic Spill Trays for Your Industrial Needs - Regulatory Compliance: Ensuring Spill Trays Meet Environmental Standards

| Spill Tray Type | Material | Capacity (Liters) | Compliance Standard | Features |

|---|---|---|---|---|

| Standard Spill Tray | Polyethylene | 120 | EPA 40 CFR 264.175 | UV Stabilized, Lightweight |

| Heavy-Duty Spill Tray | High-Density Polyethylene | 200 | NFPA 30 | Corrosion Resistant, Forkliftable |

| Stackable Spill Tray | Polypropylene | 150 | ASTM F726 | Space Saving, Lightweight |

| Drip Tray | Steel with Coating | 50 | ISO 14001 | Durable, Rust Resistant |

| Customizable Spill Tray | Recycled Plastic | Varies | Local Environmental Regulations | Custom Sizes, Eco-Friendly |

Related Posts

-

Ultimate Guide to Choosing the Best Spill Tray for Chemicals Based on Your Needs

-

10 Best Plastic Drip Trays for Ultimate Cleaning and Protection in 2023

-

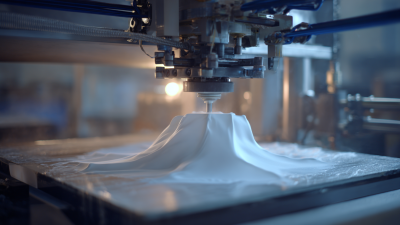

Understanding the Process of Vacuum Forming Plastic: A Beginner's Guide

-

Understanding the Excellence of the Best CNC Machine Available

-

Maximize Kitchen Cleanliness with the Ultimate Guide to Choosing a Large Drip Pan

-

7 Essential Tips for Mastering Vacuum Forming in Your Production Process