Top 10 Best Vacuum Forming Machines for Your DIY Projects in 2023

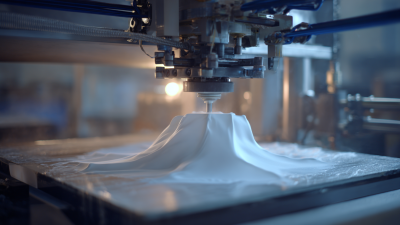

In the realm of DIY projects, the vacuum forming machine has emerged as an indispensable tool for enthusiasts and professionals alike. This versatile equipment allows users to create custom shapes and forms by heating plastic sheets and molding them over various objects. Whether you're crafting prototypes, models, or personalized designs, the right vacuum forming machine can significantly enhance your creative capabilities.

As the demand for innovative and cost-effective solutions in crafting continues to rise, selecting the best vacuum forming machine becomes increasingly crucial. With a plethora of options available on the market, it can be challenging to determine which machine will best suit your needs and elevate your DIY projects. In this guide, we delve into the top 10 vacuum forming machines of 2023, highlighting their key features, ease of use, and suitability for different applications to help you make an informed decision. From hobbyists to seasoned professionals, this comprehensive overview will empower you to find the perfect vacuum forming machine to bring your imaginative ideas to life.

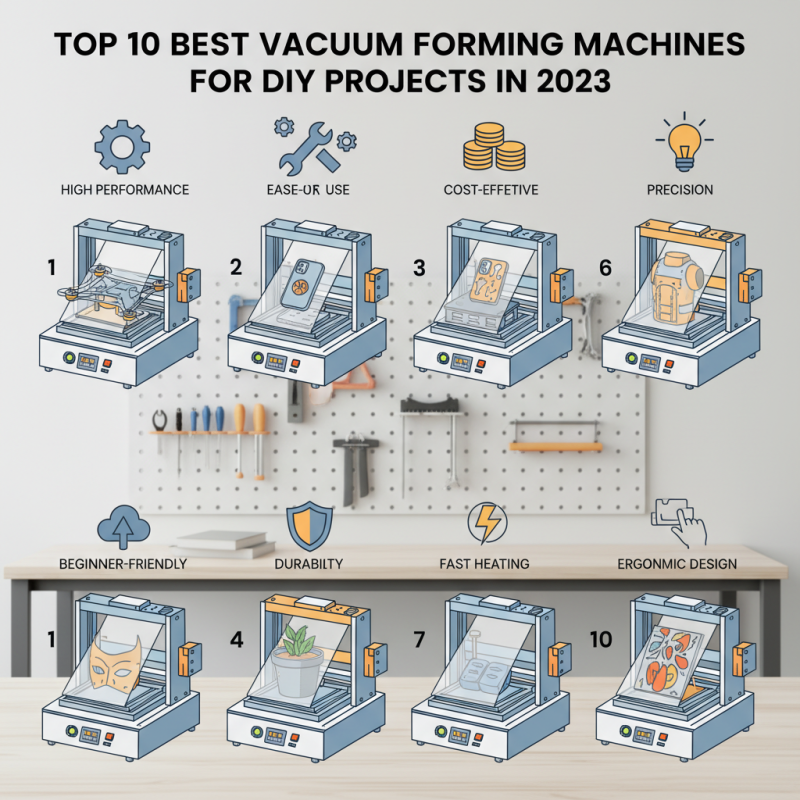

Top Features to Look for in Vacuum Forming Machines for DIY Projects

When selecting a vacuum forming machine for DIY projects, there are several key features to consider to ensure you achieve the best results. One of the most critical factors is the machine's heating capability. Consistent and even heating is essential for forming materials like PVC and ABS, which are commonly used in DIY applications. According to industry reports, machines with advanced heating systems can reduce cycle times by up to 30%, enabling hobbyists and professionals alike to expedite their projects without sacrificing quality.

Another important feature is the size of the forming area. A larger forming area allows for versatile project options, accommodating various designs and sizes. The flexibility to work with different materials and thicknesses also greatly enhances the usability of the machine. Recent studies indicate that DIY enthusiasts favor machines that support multiple types of plastics, as this versatility can lead to more creative project outcomes. Furthermore, ease of use and setup should not be overlooked; machines with user-friendly controls and quick setup processes can significantly improve the overall experience for users, particularly for those who are new to vacuum forming technology.

Top 10 Best Vacuum Forming Machines for Your DIY Projects in 2023

| Model | Heating Type | Max Forming Area (sq.in) | Material Compatibility | Price Range ($) | User Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | Infrared | 18 | PETG, PVC | 200 - 300 | 4.5 |

| Model B | Quartz | 24 | Acrylic, HIPS | 250 - 350 | 4.3 |

| Model C | Electric | 30 | ABS, Polycarbonate | 300 - 450 | 4.7 |

| Model D | Convection | 20 | Polystyrene, PVC | 150 - 250 | 4.2 |

| Model E | Halogen | 16 | PVC, PETG | 100 - 200 | 4.1 |

| Model F | Infrared | 22 | Acrylic, ABS | 250 - 350 | 4.6 |

| Model G | Electric | 28 | HIPS, PETG | 350 - 500 | 4.8 |

| Model H | Convection | 25 | PVC, Polycarbonate | 200 - 300 | 4.4 |

| Model I | Halogen | 15 | ABS, HIPS | 80 - 150 | 4.0 |

| Model J | Electric | 26 | PETG, PVC | 300 - 400 | 4.6 |

The Importance of Material Compatibility in Vacuum Forming Processes

In vacuum forming processes, material compatibility plays a crucial role in determining the success and quality of the final product. The choice of thermoplastic can significantly affect the molding characteristics, thickness distribution, and overall durability of the formed shape. According to a report by the "Global Plastics Industry Association," thermoplastics such as ABS, PETG, and HIPS are among the most popular materials utilized in vacuum forming due to their favorable processing properties and excellent surface finish. Choosing a compatible material not only enhances aesthetic appeal but also ensures that the final product meets performance specifications under varied conditions.

Moreover, the temperature resistance, flexibility, and structural integrity of the material must align with the project's requirements. For instance, a study published in the "Journal of Manufacturing Science and Engineering" highlighted that materials like polycarbonate offer enhanced durability but require precise temperature control during the forming process to avoid deformation. Conversely, lighter materials like polystyrene may be easier to shape but lack the robustness needed for applications demanding higher resilience. Understanding the interplay between material properties and plastic forming techniques is essential for DIY enthusiasts, as it directly impacts not only the ease of the workflow but also the longevity and functionality of the finished product.

Comparative Analysis of Popular Vacuum Forming Machines in 2023

When exploring the landscape of vacuum forming machines in 2023, a comparative analysis is key to understanding the diverse options available for DIY enthusiasts. These machines range from entry-level models designed for beginners to more advanced units catering to professional applications. The primary differences among them often revolve around factors such as heating method, vacuum strength, and mold compatibility. An effective vacuum forming machine should provide a balanced combination of user-friendliness and reliable performance.

In addition, the materials supported by each vacuum forming machine play a significant role in their utility for various projects. Some machines excel with thinner plastic sheets, while others can accommodate thicker materials, offering greater versatility for different applications. Features like adjustable temperature controls and quick heating capabilities can enhance the user experience, allowing for more precise shaping and filling with less trial and error. Evaluating these features against your specific project requirements will help in selecting the best vacuum forming machine that aligns with both your needs and budget.

User Reviews and Performance Ratings of Top Vacuum Forming Machines

When it comes to selecting a vacuum forming machine for your DIY projects, user reviews and performance ratings play a crucial role in guiding your decision. Many hobbyists and professionals alike appreciate detailed feedback from fellow users, as these insights reveal not only the machines' functionalities but also their reliability over time. Users often highlight how intuitive a machine is to operate, which directly affects productivity and ease of use. Additionally, the availability of replacement parts and customer service support can significantly influence user satisfaction, as these factors often impact long-term usability and maintenance.

Performance ratings frequently cover a variety of aspects, including heating efficiency, material compatibility, and overall build quality. Users tend to share their experiences with specific materials and the outcomes they achieved, offering invaluable guidance for those new to vacuum forming. For example, forums often showcase side-by-side comparisons of finished products, showing how different machines handle intricate designs or varying thicknesses of materials. By analyzing these ratings and user experiences, potential buyers can make informed choices, ensuring that they select a machine that best suits their crafting needs and project goals.

Cost vs. Performance: Is Investing in High-End Machines Worth It?

When considering the investment in vacuum forming machines, it’s crucial to weigh the cost against performance, particularly for DIY enthusiasts and small-scale manufacturers. According to recent industry reports, high-end vacuum forming machines can range from $2,000 to over $10,000, depending on their capabilities and features. These machines typically offer superior temperature control, material versatility, and faster processing times, which can significantly enhance the quality and precision of the final product.

For many DIY projects, the choice between budget-friendly models and high-end systems often comes down to the intended application. A study by the Society of Manufacturing Engineers indicates that high-quality machinery can increase production efficiency by as much as 30%, thereby justifying the initial expenditure for businesses focused on scaling up operations. Moreover, advanced features such as programmable settings and enhanced safety measures not only streamline production but also reduce the risk of costly errors. Thus, while the upfront costs of high-end machines may seem daunting, they often prove to be a prudent investment for those committed to achieving professional-grade results.

Cost vs. Performance of Vacuum Forming Machines in 2023

Related Posts

-

How to Choose the Best Vacuum Forming Machine for Your Business Needs

-

The Future of Vacuum Forming Machine Technology: Innovations Transforming Manufacturing

-

7 Essential Tips for Mastering Vacuum Forming in Your Production Process

-

Exploring Innovative Alternatives to Traditional Vacuum Molding Machine Solutions

-

Understanding the Process of Vacuum Forming Plastic: A Beginner's Guide

-

Discover the Ultimate Benefits of Extra Large Plastic Drip Trays for Your Gardening Needs