Top 10 Benefits of Using a Thermoforming Vacuum Machine in Your Production Process

The utilization of thermoforming vacuum machines has revolutionized the manufacturing landscape, particularly in industries such as packaging, automotive, and medical devices. According to the "2023 Thermoforming Market Report," the market for thermoforming machinery is projected to reach $14.5 billion by 2025, indicating a robust growth driven by the adoption of advanced manufacturing technologies. These machines facilitate the effective molding of plastic sheets into desired shapes with unparalleled precision and efficiency.

Expert in the field, Dr. Mark Stevenson, a leading authority on thermoforming technology at the Plastics Research Institute, remarks, “The implementation of a thermoforming vacuum machine not only enhances production capabilities but also significantly reduces waste material, making it an essential tool for sustainable manufacturing.” As industries increasingly emphasize ecological responsibility, the shift towards automated and efficient production methods like those offered by thermoforming vacuum machines is becoming imperative. The benefits of integrating such machinery into production processes extend beyond efficiency, often translating into cost savings, improved product quality, and increased production speeds, making it a strategic investment for manufacturers seeking to enhance their competitive edge.

Enhancing Production Efficiency with Thermoforming Vacuum Machines

Thermoforming vacuum machines have become indispensable in modern manufacturing, significantly enhancing production efficiency. According to a report by Freedonia Group, the thermoforming market is expected to grow by 4.5% annually, reaching $8 billion by 2026. This growth is driven by the machines' ability to streamline the production process, reducing waste and optimizing material usage. With precise temperature control and rapid cycle times, manufacturers can produce high-quality components while minimizing energy consumption, leading to a more sustainable operation.

The versatility of thermoforming vacuum machines allows for the quick adaptation to various production needs, whether it’s for packaging, automotive, or consumer goods. A survey by the Packaging Association shows that 80% of manufacturers reported improved operational agility and a 30% reduction in lead times after implementing thermoforming technology. This efficiency not only boosts output but also enhances product quality, ensuring that businesses can meet rising consumer demands while maintaining competitiveness in the market.

The versatility of thermoforming vacuum machines allows for the quick adaptation to various production needs, whether it’s for packaging, automotive, or consumer goods. A survey by the Packaging Association shows that 80% of manufacturers reported improved operational agility and a 30% reduction in lead times after implementing thermoforming technology. This efficiency not only boosts output but also enhances product quality, ensuring that businesses can meet rising consumer demands while maintaining competitiveness in the market.

Improving Product Quality through Precise Forming Techniques

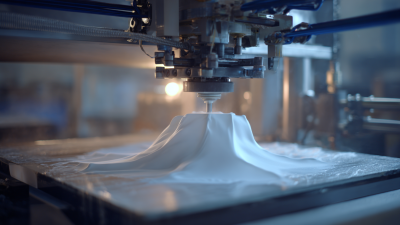

The precise forming techniques offered by a thermoforming vacuum machine significantly enhance product quality across various industries. By utilizing vacuum pressure to shape materials, manufacturers can achieve consistent results with minimal defects. This level of precision ensures that each product meets stringent specifications, leading to improved fit and finish, which is paramount in sectors such as packaging, automotive, and consumer goods.

Additionally, thermoforming allows for intricate designs and shapes that were previously difficult to achieve with traditional manufacturing methods. The ability to manipulate materials into complex forms without compromising on strength or durability means that companies can innovate and push the boundaries of product design. As a result, businesses not only improve their product offerings but also enhance their competitive edge in the market, catering to the growing consumer demand for unique and high-quality products. The investment in a thermoforming vacuum machine thus proves beneficial for both product excellence and brand reputation.

Cost-Effective Solutions: Reducing Material Waste in Production

Thermoforming vacuum machines have become pivotal in the manufacturing sector, especially when it comes to reducing material waste and optimizing production efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, companies using thermoforming technologies can reduce scrap rates by up to 30%. This significant reduction in waste is crucial for manufacturers looking to enhance their sustainability efforts while simultaneously cutting costs. By utilizing these machines, businesses not only benefit from lower material costs but also contribute to a greener production environment by minimizing their ecological footprint.

Moreover, the advancements in thermoforming technology have led to improved material usage. A study conducted by the Society of Plastics Engineers highlighted that innovative vacuum forming techniques can achieve up to 98% material utilization rates, in stark contrast to traditional methods that often fall below 70%. This surge in efficiency means that manufacturers can maximize each sheet of material, leading to lower overall production costs. In an economy where material prices fluctuate, such cost-effective solutions provide companies with a competitive edge, enabling them to operate more sustainably while enhancing their profit margins.

Versatility in Manufacturing: Adapting to Various Industries and Products

Thermoforming vacuum machines have become essential tools across various manufacturing sectors due to their remarkable versatility. According to a report by Smithers Pira, the global thermoforming market is projected to reach $24 billion by 2025, driven by a wide range of applications from packaging to automotive components. This adaptability allows manufacturers to tailor products precisely to industry needs, whether creating custom food containers, protective packaging for electronics, or intricate parts for the automotive industry.

One of the key advantages of using thermoforming vacuum machines is their ability to process numerous materials, such as plastics, metals, and composites, catering to diverse manufacturing demands. For instance, the Food and Beverage sector, which is increasingly focused on sustainability and efficiency, has adopted thermoforming technology to produce innovative packaging that meets regulatory requirements while minimizing waste. Data from the Association of Plastic Recyclers highlights that thermoformed products can be up to 30% lighter than their traditional counterparts, significantly lowering transportation costs and environmental impact. This trend underscores the importance of versatile machinery in aligning with evolving industry practices while maintaining competitive advantage.

Top 10 Benefits of Using a Thermoforming Vacuum Machine in Your Production Process

Streamlining Operations: Automation and Labor Savings in Thermoforming

The adoption of thermoforming vacuum machines is revolutionizing production lines across various industries, offering significant automation benefits that directly lead to labor savings. According to a report by Grand View Research, the global thermoforming market is set to grow significantly, projected to reach USD 12.7 billion by 2025, largely driven by advancements in technology that improve production efficiency. The integration of these automated machines not only enhances the speed of production but also minimizes the need for extensive manual labor, thus addressing labor shortages and reducing operational costs.

Moreover, the efficiency offered by thermoforming vacuum machines optimizes workflow, allowing companies to reallocate labor resources to more strategic roles within the organization. A study published by the Society of Plastics Engineers indicated that automation in manufacturing can reduce labor costs by up to 30%. With thermoforming processes that can operate with minimal human oversight, businesses can achieve higher output rates and streamline their operations, ultimately improving profitability. The ability to automate repetitive tasks not only enhances productivity but also ensures consistent quality in the final products, further emphasizing the value of integrating these sophisticated machines into production processes.

Top 10 Benefits of Using a Thermoforming Vacuum Machine in Your Production Process

| Benefit | Description | Impact on Production |

|---|---|---|

| Increased Efficiency | Automates the forming process, reducing cycle time. | Shortens production time and increases output. |

| Labor Savings | Reduces the need for manual labor in the forming process. | Lowers labor costs and reallocates workforce to more skilled tasks. |

| Improved Consistency | Ensures uniformity in product dimensions and quality. | Reduces waste and returns due to defects. |

| Enhanced Flexibility | Easily adapts to different materials and designs. | Allows quick changeovers and experimentation with new products. |

| Reduction of Waste | Maximizes material usage and minimizes scrap production. | Decreases material costs and environmental impact. |

| Faster Prototyping | Quicker turnaround on prototypes for testing and feedback. | Accelerates product development cycle. |

| Energy Efficiency | Optimizes energy use during the forming process. | Reduces operating costs and environmental footprint. |

| Better Worker Safety | Minimizes manual handling and decreases injury risk. | Promotes a safer working environment. |

| Advanced Technology | Incorporates modern technology for superior performance. | Increases competitiveness and product innovation. |

| Scalability | Easily scales production up or down according to demand. | Provides flexibility to meet market needs. |

Related Posts

-

Innovative Chinese Manufacturing Elevates Global Sales of Top Thermoforming Vacuum Machines

-

Understanding the Process of Vacuum Forming Plastic: A Beginner's Guide

-

7 Essential Tips for Mastering Vacuum Forming in Your Production Process

-

Exploring Innovative Alternatives to Traditional Vacuum Molding Machine Solutions

-

Exploring Market Trends for Plastic Drip Trays at the 138th China Import and Export Fair in 2025

-

Ultimate Guide to Choosing the Best Spill Tray for Chemicals Based on Your Needs